OUR PRODUCT

Falk Lifelign Gear Couplings’ triple-crowned teeth are crowned on the root, tip and face to articulate freely and minimize wear caused by misalignment. By eliminating tip-loading while reducing backlash and radial clearances, Lifelign’s triple-crown teeth can help protect equipment from damaging loads.

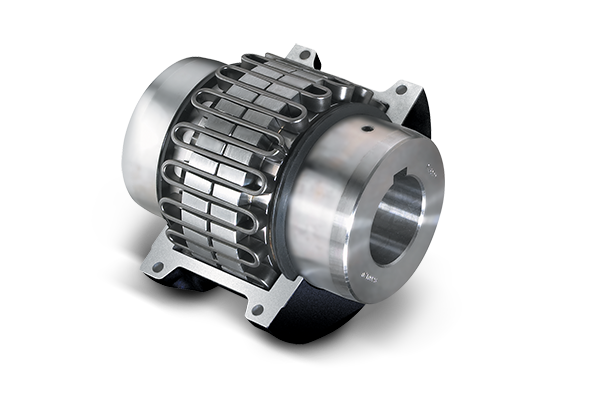

Rexnord has been manufacturing and improving our Falk Steelflex Grid Couplings for nearly a century. Known for durability in critical applications, proven performance and versatile design, these couplings are the most frequently specified grid coupling in North America.

Highest torque and bore capacity jaw coupling (compared to L & C Type).Elastomeric cushions are radially removable.Accommodates for angularand parallel shaft misalignmentFail-safe (will still perform if elastomeric cushions fail).No coupling grease required; no metal to metal contact.Resistant to oil, dirt, sand, moisture, and grease.

HOT PRODUCT

Rexnord Elastomeric Couplings are ideal for a wide assortment of industries and have been trusted by many of the largest OEM machinery equipment suppliers and end users for over 45 years. These non-lubricated, material-flexing couplings can be used in a variety of environments. They provide excellent vibration-damping capability, high-misalignment capacity, reduced maintenance costs and downtime, in addition to special design options for specific applications.

- Lightweight aluminum version of the industry standard shaft coupling

- Interchangeable with L and SS line of hubs (except AL150)

- Corrosion resistant (finished bores passivated for additional protection)

- Accommodates for angular and parallel shaft misalignment

- Fail-safe – will still perform if elastomer “spider” fails

- No metal to metal contact

- Resistant to oil, dirt, sand, moisture, and grease

- Stainless steel version of the industry standard shaft coupling

- Interchangeable with L and AL line of hubs (except AL150)

- Finished bores passivated for added rust protection

- Accommodates for angular and parallel shaft misalignment

- Fail-safe (will still perform if elastomeric “spider” fails)

- No metal to metal contact

Product data characteristics

SOX (NBR) Rubber (Standard Insert) – Nitrile Butadiene (Buna N) Rubber is a flexible elastomer material that is oil resistant, resembles natural rubber in resilience and elasticity.

Urethane – Greater torque capability than NBR (1.5 times), provides less dampening effect, and operates in a smaller temperature range. Good resistance to oil and chemicals. Not recommended for cyclic or start/stop applications.

Hytrel® – Flexible elastomer designed for high torque and high temperature operations. Excellent resistance to oil and chemicals. Not recommended for cyclic or start/stop applications.

Bronze – Rigid, porous oil-impregnated metal insert exclusively for low speed (max 250 RPM) applications requiring high torque capabilities. Not affected by extreme temperatures, water, oil, or dirt.

|

Material |

Temperature |

Misalignment |

Shore |

Dampening |

Chemical |

Color |

|

|

|

|

Angular |

Parallel |

||||

| SOX (NBR) Rubber |

-40°F to 212°F |

1° |

0.015 |

80A or 60A* |

High |

Good |

Black |

| Urethane |

-30°F to 160°F |

1° |

0.015 |

55D or 90-95A** |

Low |

Very Good |

Blue |

| Hytrel® |

-60°F to 250°F |

1/2° |

0.015 |

55D |

Low |

Excellent |

Tan |

| Bronze |

-40°F to 450°F |

1/2° |

0.01 |

– |

None |

Excellent |

Bronze |

* All Sizes (except L035) shore hardness = 80A, Size L035 shore hardness = 60A

** Sizes L050 to L110 shore hardness = 55D, Sizes L150 to L225 shore hardness = 90-95A

Note: In addition to solid center spiders (most common), open center spiders are also available (to allow shafts of the driver and driven to be positioned within a short distance). Open center spiders offer shaft positioning flexibility but have a lower RPM capacity (1,750 RPM maximum for NBR, 3,600 maximum for Urethane and Hytrel®).